Have you ever thought about where your beauty products come from?

While anyone can formulate at home, do you know where the global beauty industry makes its products? The answer is: factories. And most of us never get to see inside them. But we got an exclusive factory tour to show you what really goes on behind the scenes.

As part of our research for the relaunch of our Advanced Diploma in Organic Cosmetic Science, the Formula Botanica team visited Mayfield Labs, a leading contract manufacturer in the southwest of the UK, to see how cosmetic products are made at scale. And filmed the entire factory tour for you. Here’s what we got up to.

Entering the factory: complying with GMP

The first step inside any manufacturing facility? GMP.

Before we could even set foot on the factory floor, Good Manufacturing Practice (GMP) protocols kicked in. We sanitised our hands, donned PPE (Personal Protective Equipment), and followed strict hygiene measures.

At a contract manufacturer like Mayfield Labs, GMP is central to every part of production – exactly what we teach in our courses, just applied on a much larger scale.

Raw material storage & quality control area

Once inside, our tour took us through aisles stacked with drums of glycerine, surfactants, botanical oils, and other familiar ingredients. It was incredible to see the raw materials we teach in our courses in such industrial quantities.

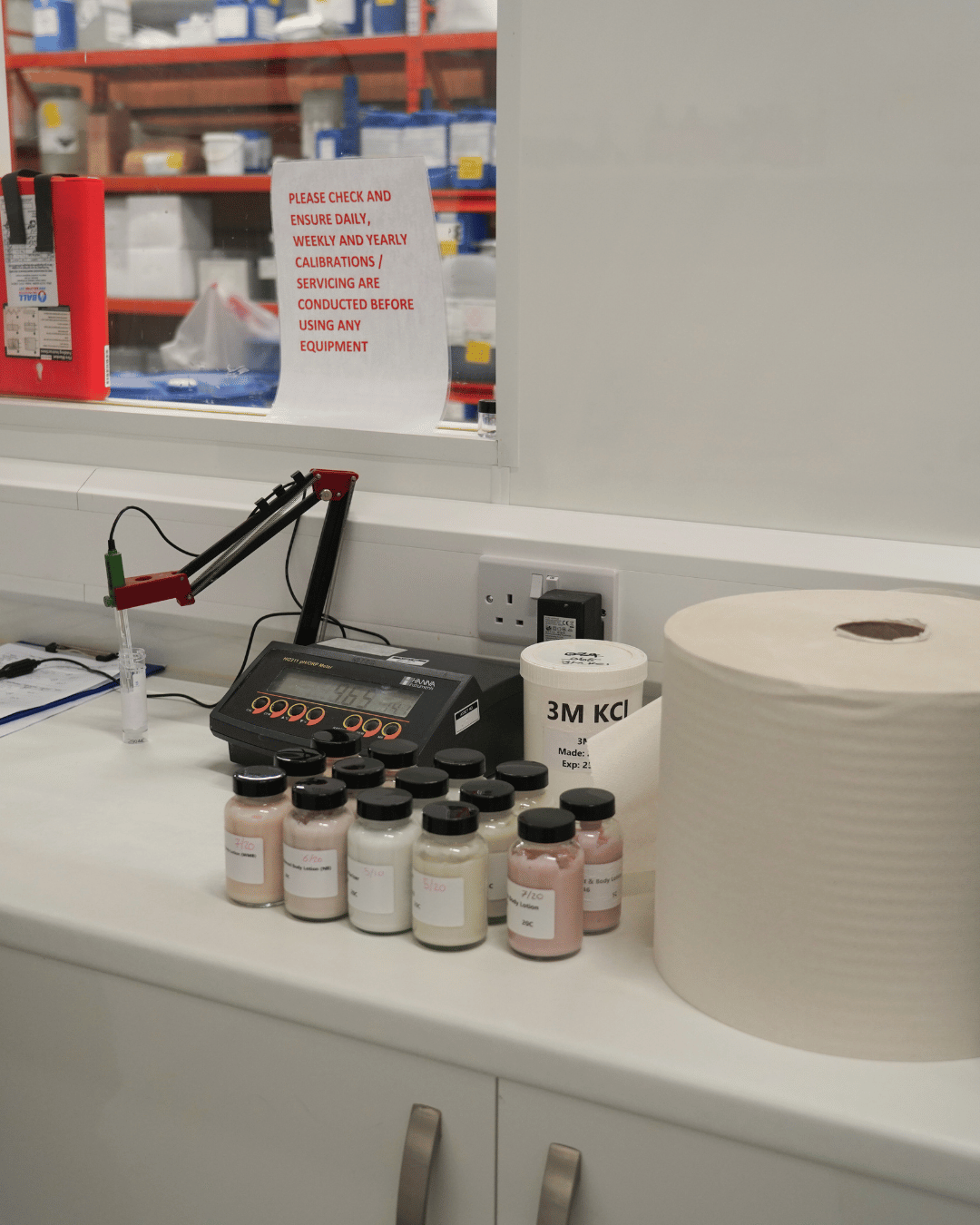

At Mayfield, a dedicated quality control area also ensures that every raw material is checked before use – a crucial step at any contract manufacturer.

Seeing a formulation come to life

Then came the most exciting part of the factory tour: watching a formulation take shape. Once raw materials pass quality control, they’re used to create small-batch prototypes – just like in your home lab, but on a much larger scale.

Designing a prototype

We then stepped into the main manufacturing and formulation area, where formulations are developed, tested, and refined. At Mayfield Labs, you can either bring your own formula or have it created for you, fully from scratch.

The lab team then creates small-batch prototypes to perfect texture, scent, pH, and performance. Every product starts as a small-scale trial. And once it’s proven to be stable, it moves on to manufacturing.

We also got a peek at a tabletop homogeniser, used to combine the oil and water phases of an emulsion, similar to the one we recommend in our advanced formulation course.

Large-scale manufacturing

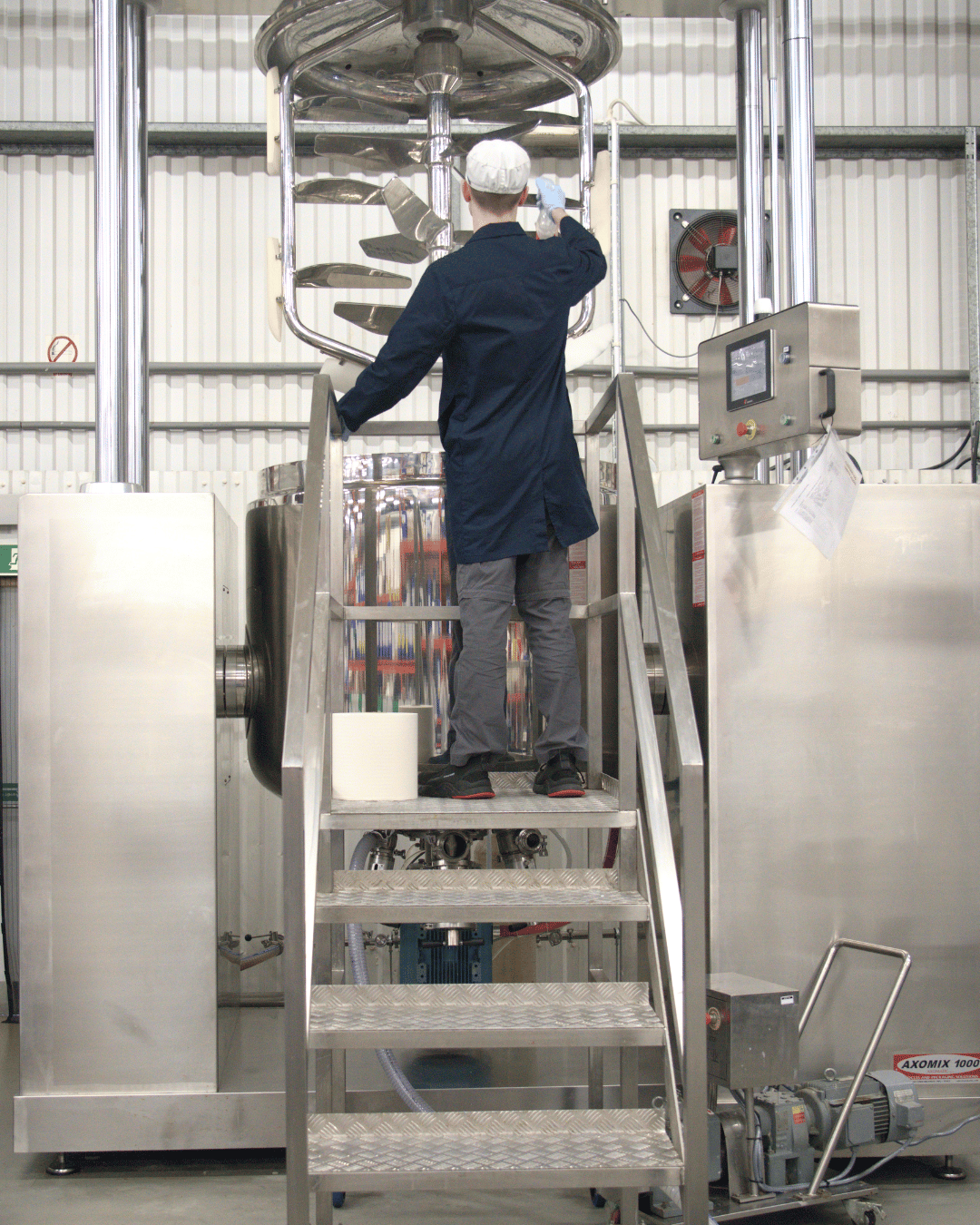

Next on our factory tour, we moved to the manufacturing area, where we saw all sorts of fascinating, huge equipment. This was much bigger than anything you would find in a home lab. If you’re an indie brand looking to scale up, this is where you would go to make thousands and thousands of units.

On this particular day, we saw 1 tonne (!) of lotion being mixed in a single mixing vessel. Yes, you’ve read that right: 1 tonne. That’s 1,000 litres of product being mixed in a single vessel. So, every time you buy a lotion, a conditioner, or a hand cream from a big brand, it typically comes from a factory like this.

Watching the process of creating a hand and body lotion from start to finish was incredible. The manufacturing team warmed the water and oil phases separately, carefully monitored temperatures, added powders, and then blended everything in a heated mixing vessel under vacuum.

This might sound very familiar to you if you’ve ever made a lotion at home before. The only difference is that here, it was on an industrial scale, with much larger equipment!

Medium-scale manufacturing

Mayfield also caters to mid-sized brands that aren’t yet producing by the tonne. During our factory tour, we saw their 300-litre mixing vessels, which are ideal for scaling up when you’re ready to move beyond your kitchen but aren’t quite supplying global retailers yet.

This kind of flexibility is exactly why many indie formulators choose to partner with contract manufacturers as they grow. It allows them to scale their production without the heavy upfront investment in lab equipment.

Wondering when it’s the right time to work with a contract manufacturer? Enrol in our Diploma in Beauty Brand Business Management to find out!

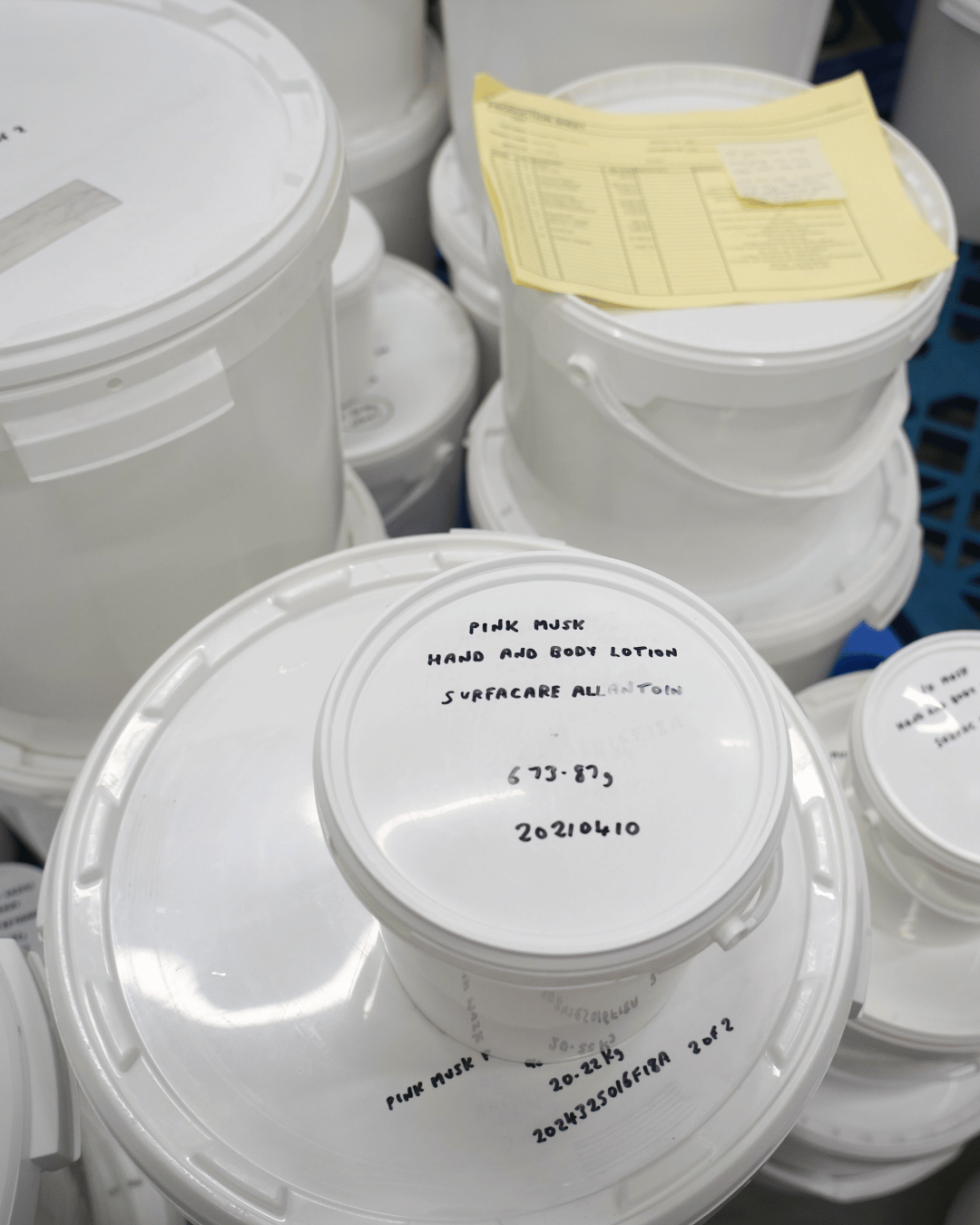

What happens before production

Before anything is mixed, all ingredients are carefully pre-weighed in a separate area.

This step helps ensure that production runs smoothly and that each batch is consistent with the one before. During our factory tour, the pre-weighing area was lined with neatly labelled buckets, all prepared for an upcoming deodorant run.

It’s a great reminder to prep as much as you can before you formulate. Good prep reduces the chance of errors, whether you’re making a batch of 100 grams or 100 kilograms of deodorant.

Special processes for certain products

We also got to witness the production of an alcohol-based body spray. Because alcohol is highly flammable, the production team used an air-powered stirrer instead of a traditional electric mixer, which shows that equipment and processes must be carefully matched to each formulation.

Storage area & testing

After production, every batch is held in a quarantine zone and tested again.

Products are checked for pH, viscosity, scent and appearance (against the previous batch) and microbial safety (Mayfield Labs outsources this.)

Nothing moves to packaging until it’s passed all checks. These safety and stability steps are non-negotiable for the team – after all, you want only safe, stable products on your skin or hair. It’s the same rigorous approach we teach in our formulation courses.

The final step: packaging & labelling

Now came the part that was oddly satisfying to watch.

Once a batch is approved, it’s pumped into bottles using semi-automated equipment. Caps are applied with precise torque. Labels are applied by machine. And every bottle is batch-coded for traceability.

During our visit, the people at Mayfield filled over 1,000 bottles of lotion in under two hours. Every 30 minutes, the team paused to check cap tightness, fill weight, and label placement, ensuring every unit met their quality standards. It was super satisfying!

Final packaging and palletising

Once filled, the products were shrink-wrapped into bundles, boxed, palletised, and separated by whether they’re hazardous (alcohol-based, for example) or not.

Seeing rows of pallets ready to ship was a powerful moment because these weren’t just random products. They were the scaled-up versions of formulations just like yours.

And that’s a wrap of our factory tour! The products were ready to be shipped, and we headed out after a fun and insightful day at Mayfield Labs.

Ready to scale? Watch the full factory tour now

If you’ve ever wondered what it takes to manufacture your cosmetic products at scale, from raw materials to finished, retail-ready products, you need to watch this factory tour.

This is a rare, behind-the-scenes look at what happens inside a cosmetic production facility. It’s also a great reminder that every product has a story. Behind each lotion, toner, or serum is a team of people, a rigorous process, and a commitment to quality. And it all starts with formulation.

Whether you’re a curious formulator or an indie brand owner preparing to scale, we hope this factory tour inspires you to take that next step in your formulation journey.

FREE TRAINING

Learn how to become an

Organic Skincare Formulator

FREE TRAINING

How to become an

Organic Skincare Entrepreneur

FREE TRAINING

How to become an

Organic Skincare Entrepreneur

Leave us a comment

Ariane is Formula Botanica’s Content Creator and an active member of the student community. She has worked as a professional journalist, blogger, copywriter and editor before joining Formula Botanica full-time in 2024.