If you’ve ever thought about scaling your indie beauty brand but don’t know where to start, this post is for you.

Like many of our Formula Botanica graduates, you might have reached a stage where small-batch production just isn’t sustainable anymore. And maybe, like them, you love formulating, but can’t realistically keep making everything yourself.

That’s when it’s time to consider working with a contract manufacturer, who will make your products for you. But how do you approach a contract manufacturer? And what do you need to know beforehand?

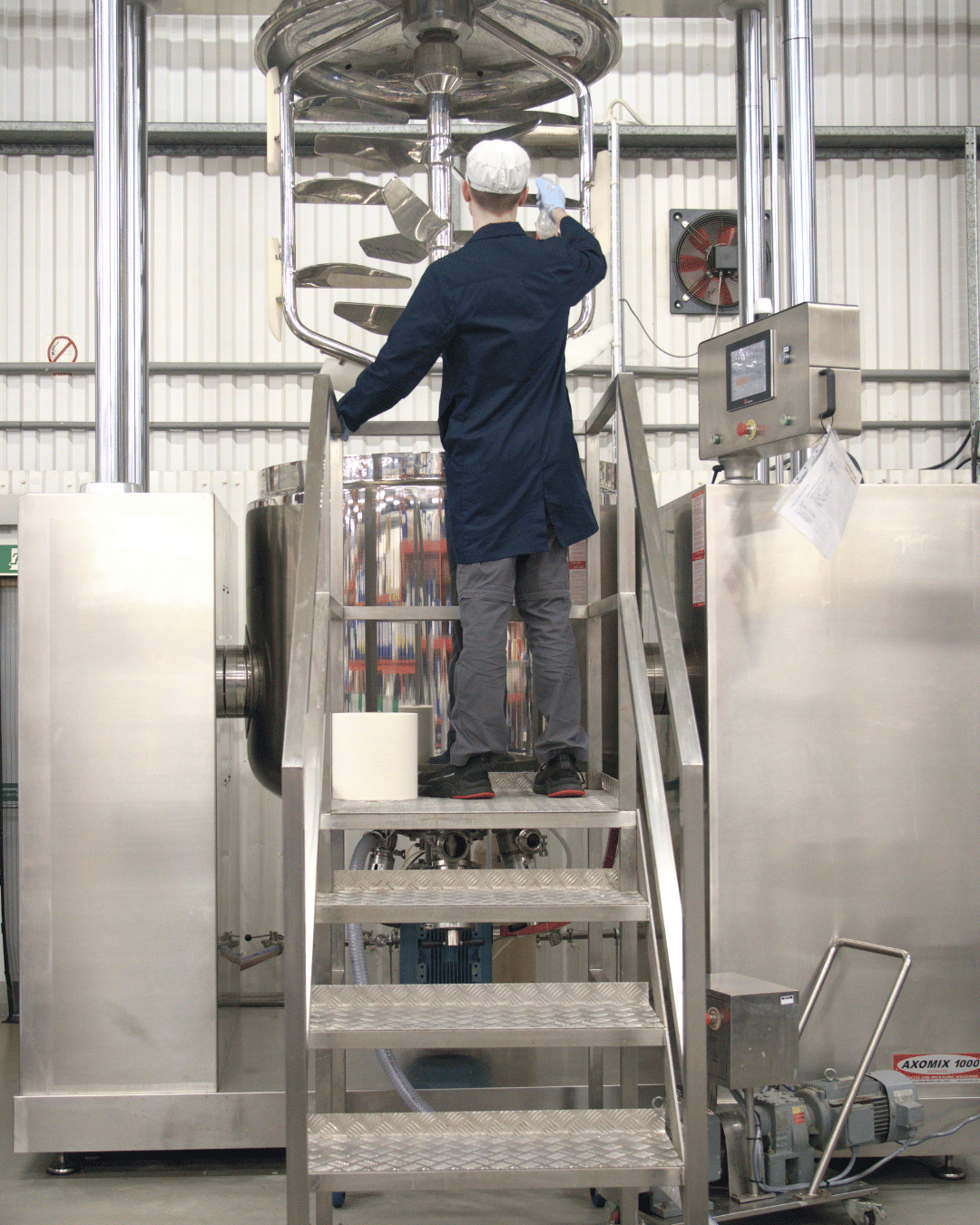

To help you navigate this journey, our CEO, Lorraine Dallmeier, interviewed Lucy Poole, General Manager at Mayfield Labs, a leading contract manufacturer in the UK. Mayfield manufactures for over 40 beauty brands, from small indie brands to international franchises, and their manager, Lucy, had a lot of knowledge to share. Here’s what she said.

Q&A with Lucy Poole, General Manager at Mayfield Labs

We even filmed it all for you on our YouTube channel. Here are the key highlights.

Hi Lucy! Can you tell us more about Mayfield Labs?

Hi Lorraine! Sure. Mayfield started probably about 40 years ago in London. Like so many indie brands, and similarly to what your students do, the founder started making products in his kitchen.

He quickly started selling to beauty schools across London and then moved to a larger site in the southwest, where Mayfield grew into what it is today.

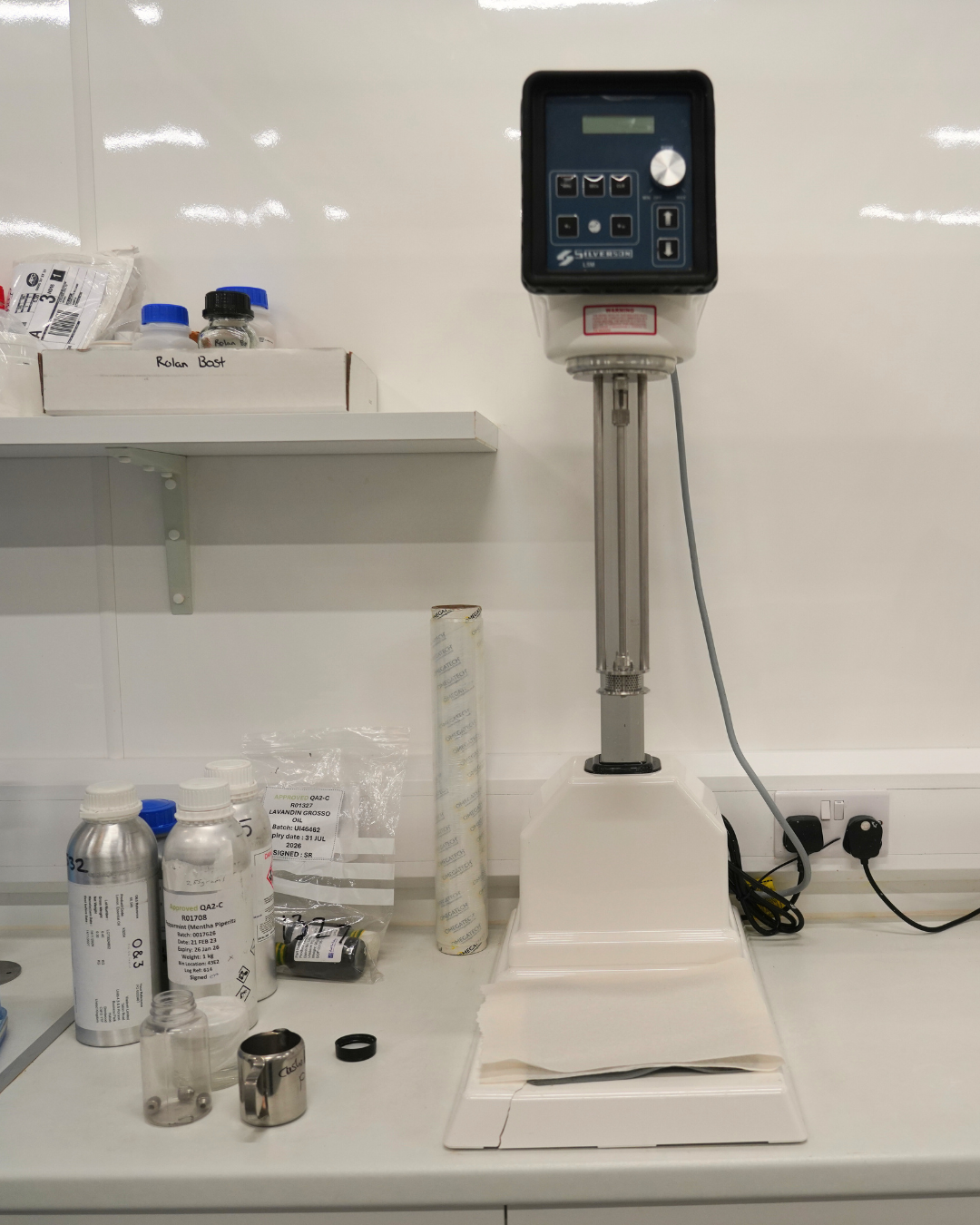

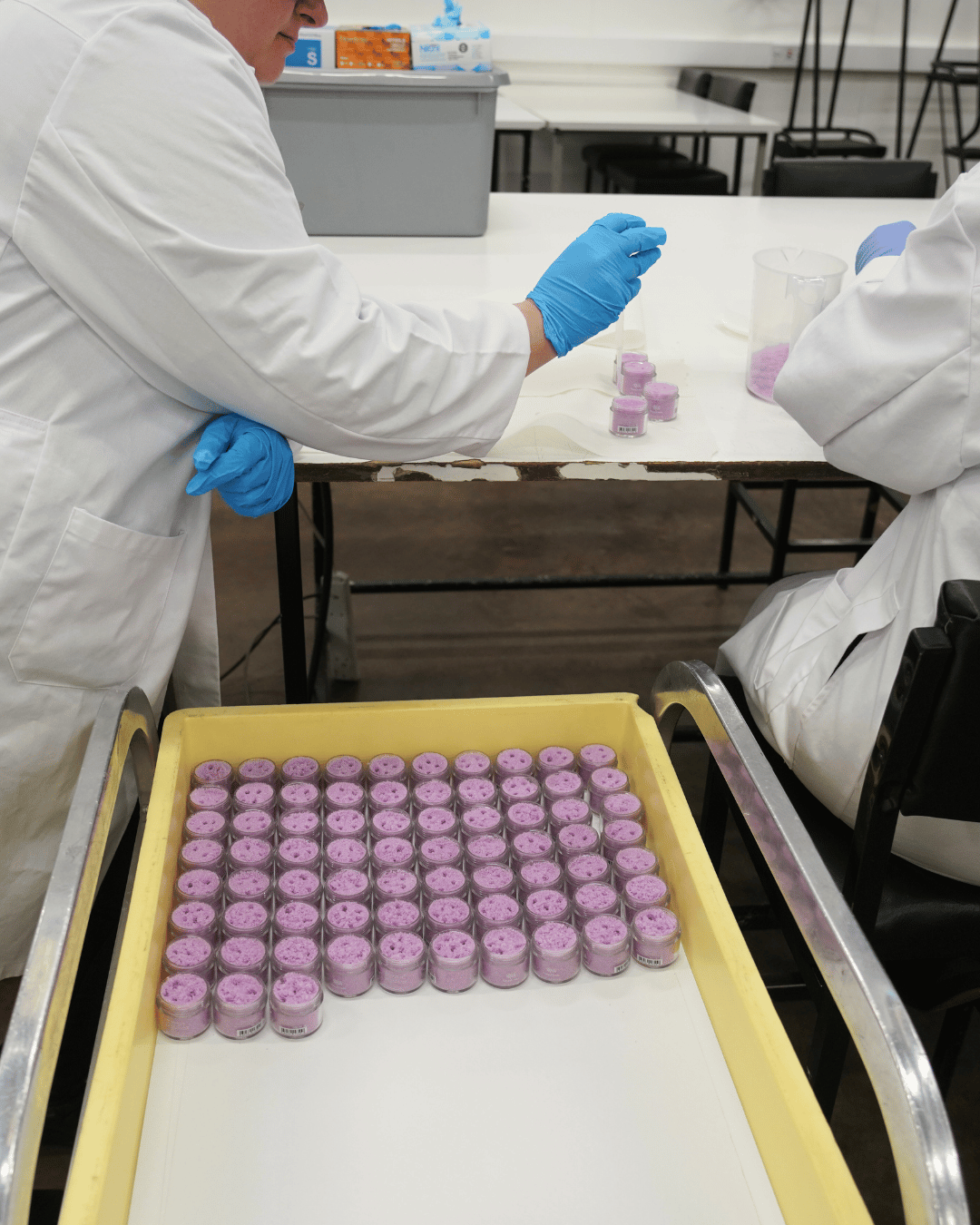

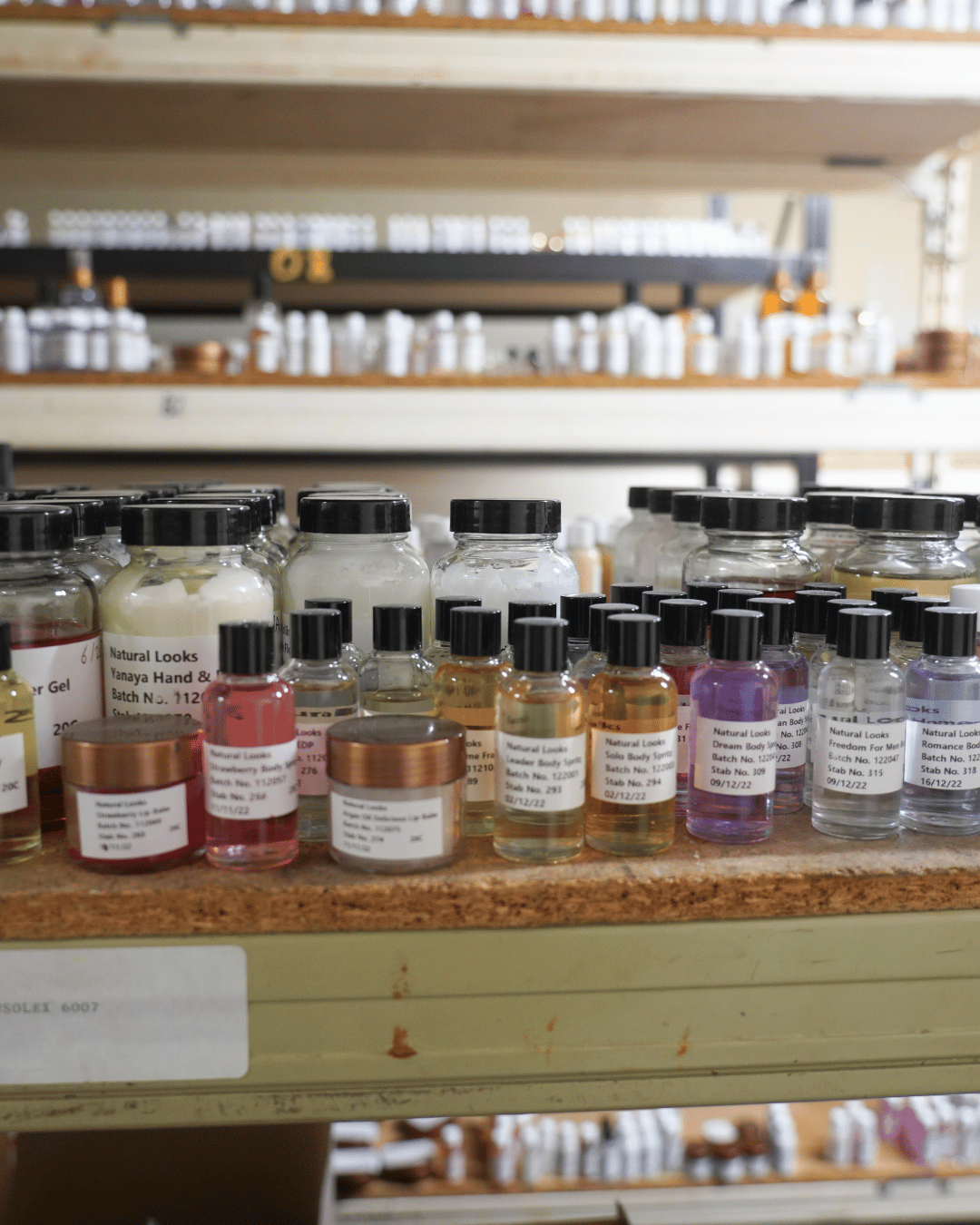

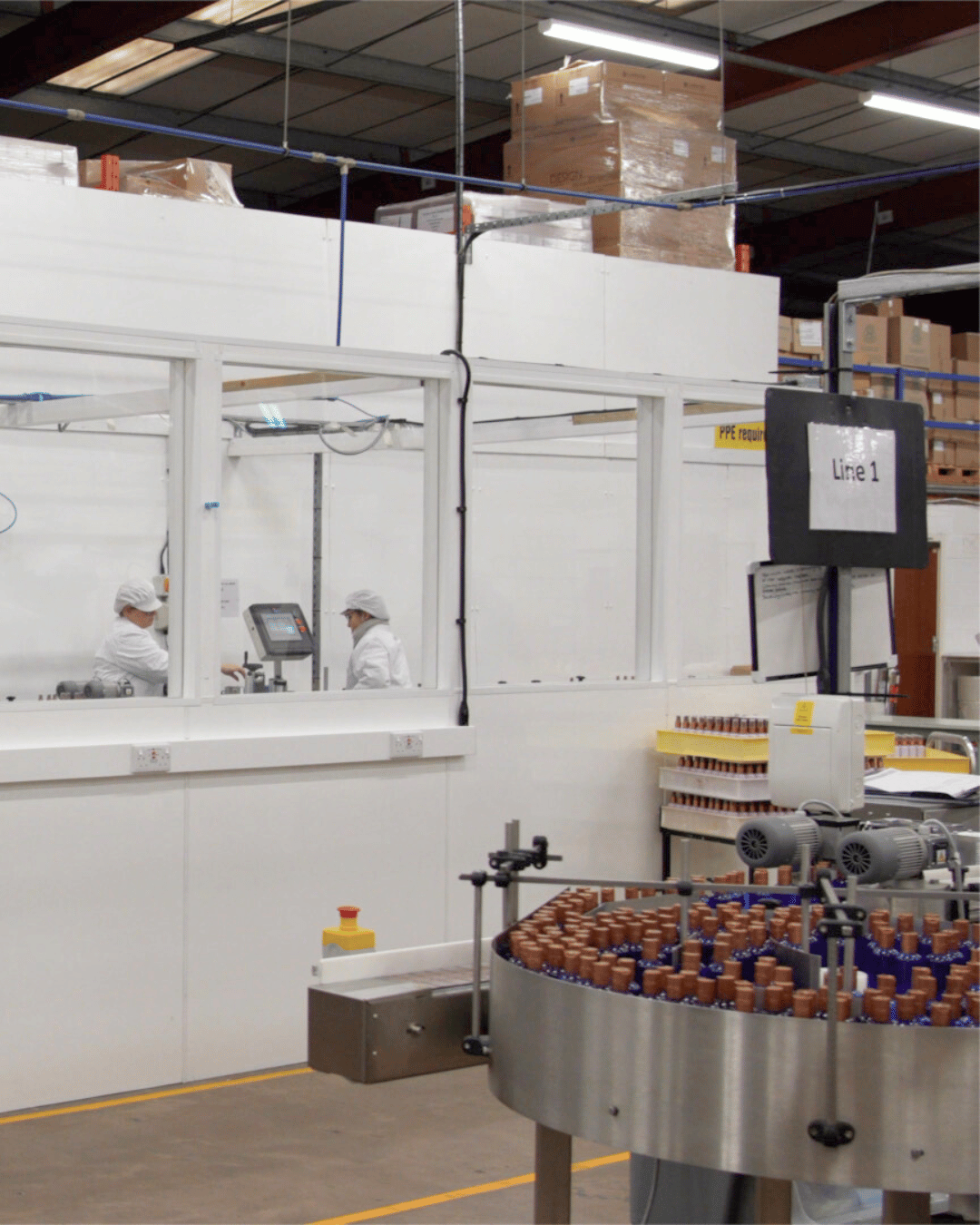

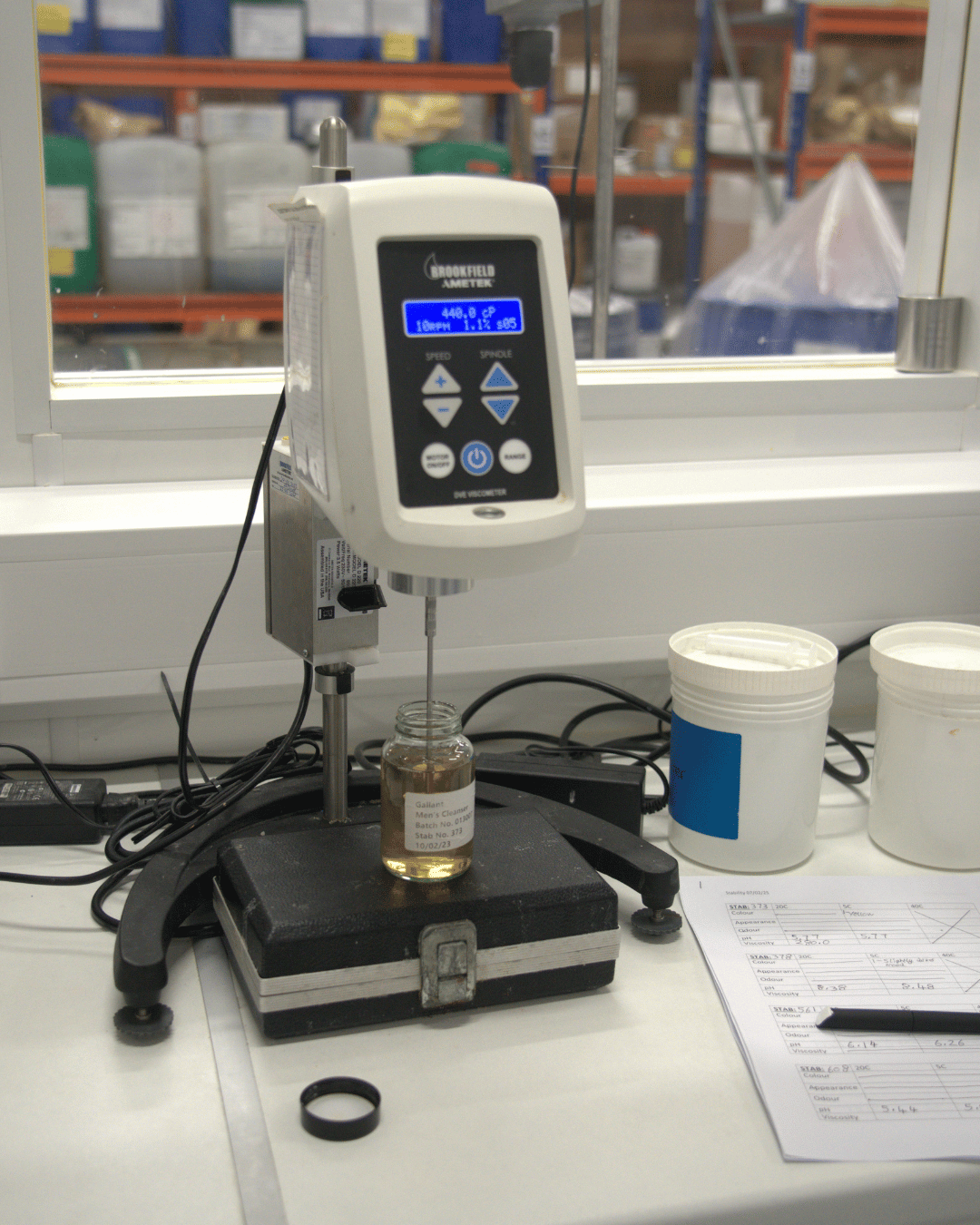

Now, we have multiple units and handle everything from R&D and manufacturing to filling, labelling, packaging and storing. We manufacture for over 40 beauty brands worldwide.

What’s the biggest difference between making your own products and hiring a manufacturer?

We also take small orders, starting from just 25kg or 250 units, which makes them accessible to small startup brands that aren’t ready for huge quantities yet. We love to support small indie brands, as we can also grow with them as they scale.

What do you need before approaching a manufacturer?

It depends on where you’re at in your business journey. If you need help with the formulation, Mayfield offers a product development service, where we can produce samples and arrange all of the stability and challenge testing and fill the CPSR (Cosmetic Product Safety Report) for you.

If that’s the case, you’ll be asked to fill out a product brief detailing:

- What kind of product you want to create

- Key ingredients (and which to avoid)

- Your desired performance, texture, and scent

- Your price point and target customer

From there, our chemist will assess whether your idea is viable or not and quote you a development fee. Keep in mind that pricing, ingredient expectations, and certification goals need to be realistic, so you’ll need to make trade-offs sometimes.

If, on the other hand, your formulation is finished and you’ve already done all of the legal compliance and testing, but just need someone to manufacture your products for you, you’ll need to give us:

- Your full formulation, with the ingredients’ trade names (not just INCI)

- The suppliers for your ingredients (as an ingredient will change from one supplier to another)

- The specific gravity of your product (products are usually labelled by volume, so you need to transpose it from weight to volume)

- Packaging specifications (e.g. bottle vs jar, label placement, carton or not)

- Unit size and number of units you’d like to order

The more detail, the better it is. You can’t give too much!

Can you use your original ingredients and packaging?

Yes, you can – but there are a few important things to keep in mind.

When it comes to ingredients, we’ll ask where you’ve sourced your raw materials. If we recognise the material, or if the INCI name matches something we already stock, we’ll let you know and suggest using our version instead. It’s often easier and more efficient for everyone if we can use ingredients already in our system, rather than stocking multiple versions of the same material.

If you’re using a very specific active that we don’t currently carry, we can still source it for you. However, you may need to purchase the full quantity, even if your production run only requires a small amount. In that case, you’d be responsible for covering the cost of any leftover material.

As for packaging, you’ll need to supply everything: bottles, caps, jars, labels, cartons. We don’t provide packaging ourselves, but we’re happy to recommend trusted suppliers you can work with!

What are some common misconceptions about working with a manufacturer?

One of the biggest? Expecting an instant quote.

Many new brand owners will call and say, “I want to make your minimum order of shampoo. What’s the cost per bottle?” But it’s not that simple. Without knowing your formulation, ingredients, packaging, and volume, no manufacturer can give you an accurate answer.

What happens when you’re ready to move forward?

If everything is in place – your formulation, packaging, paperwork, and pricing agreement – we will produce a small sample batch to make sure the product meets your expectations.

Once it’s approved and you’re happy with it, you can place your order, pay the invoice, and production begins. Six to weeks, eight weeks later, you should have your 250 (or however many you need) units of product!

Does Mayfield work with global brands?

Yes, we work with brands all over the world and can ship internationally without any issues.

The only exception is the U.S., where we need to invoice a UK-registered company. This could be your own UK entity or a distributor based in the UK. But as long as that structure is in place, we’re happy to manufacture products for the U.S. market.

Are there any rising ingredients or product trends lately?

There’s a rise in sunscreen formulations, especially natural and mineral-based options. These are more complex and expensive to formulate and test, but they’re in high demand.

We’ve also seen waves of interest in beard oils, men’s skincare and other niche categories.

If someone isn’t ready to work with a contract manufacturer yet, what steps should they take?

The most important thing is to be well on track with your testing and compliance work. You’ll save yourself a huge amount of time, stress, and back-and-forth if all of that is sorted in advance.

Once you’ve finalised your formulation, you’ll need to complete stability testing and challenge testing, and have a full cosmetic safety assessment in place. Understanding these requirements – and starting them early – will put you in a much stronger position when you’re ready to move into manufacturing.

If you haven’t done these, you could be looking at a 6-month delay before production can begin. Having that clarity upfront makes the transition to working with a manufacturer much smoother and more successful.

What’s the one piece of advice you have for someone considering contract manufacturing?

Make sure you have a solid understanding of your formulation – how it works, what each ingredient does, and where everything comes from. That foundation is essential.

It’s also incredibly important to build a strong, communicative relationship with your manufacturer – whether that’s us or someone else. Clear communication goes a long way.

And remember, there’s no such thing as a stupid question. If you’re unsure about something, just ask. We’re here to help, and we’d much rather walk you through it than have you guess.

What does your ideal client look like?

The ideal client is well-prepared, with all their paperwork in place, a clear and complete formulation, and a solid understanding of how long things take.

For example, if someone contacts us and says they’ve got a formulation, they’re planning to start testing and safety assessments, and they’re aiming to launch in 18 months – that’s fantastic. It means we have the time to do things properly, without the pressure of unrealistic deadlines.

A good grasp of timelines, realistic expectations, and a well-organised approach goes a long way. That level of preparation makes the entire process smoother and more enjoyable for everyone involved.

How can people get in touch with Mayfield?

The easiest way is to visit our website at mayfieldlabs.co.uk. You’ll find a ‘Contact Us ‘ section with our email address and phone number. Just drop us a message or give us a call – we’re always happy to have a chat and see how we can help!

Ready to scale your beauty brand?

As shared in this interview, scaling isn’t about giving up control: it’s about growing your impact while staying true to your vision. Partnering with a manufacturer like Mayfield Labs can provide you with the support, structure and scale to take your formulations to the next level, no matter the size of your brand.

Want to hear more? Watch the full video interview with Lucy Poole on our YouTube channel and get insider tips on working with a contract manufacturer, including how to move your beauty business from your kitchen to a professional lab.

Curious about how to scale your indie brand? Check out our Diploma in Beauty Brand Business Management and learn how to confidently build and scale a thriving beauty brand.

FREE TRAINING

Learn how to become an

Organic Skincare Formulator

FREE TRAINING

How to become an

Organic Skincare Entrepreneur

FREE TRAINING

How to become an

Organic Skincare Entrepreneur

Leave us a comment

Ariane is Formula Botanica’s Content Creator and an active member of the student community. She has worked as a professional journalist, blogger, copywriter and editor before joining Formula Botanica full-time in 2024.